| SECOND HAND MACHINE |

| |

| SC-23006 |

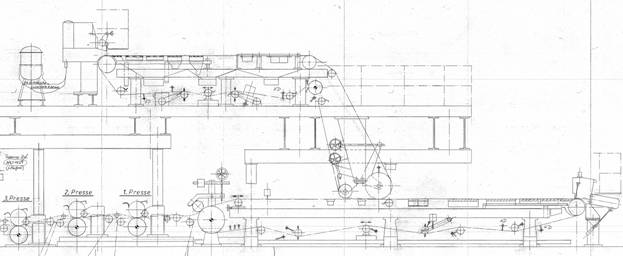

2250mm Corrugated Paper Machine |

|

1 second-hand Fourdrinier Paper Machine with Top Wire Make :

Bruderhaus, Bellmer and others

|

|||

|

Consisting of: Stock Preparation including Top Layer Approach Flow System with

|

|||

|

Paper Machine including

|

|||

|

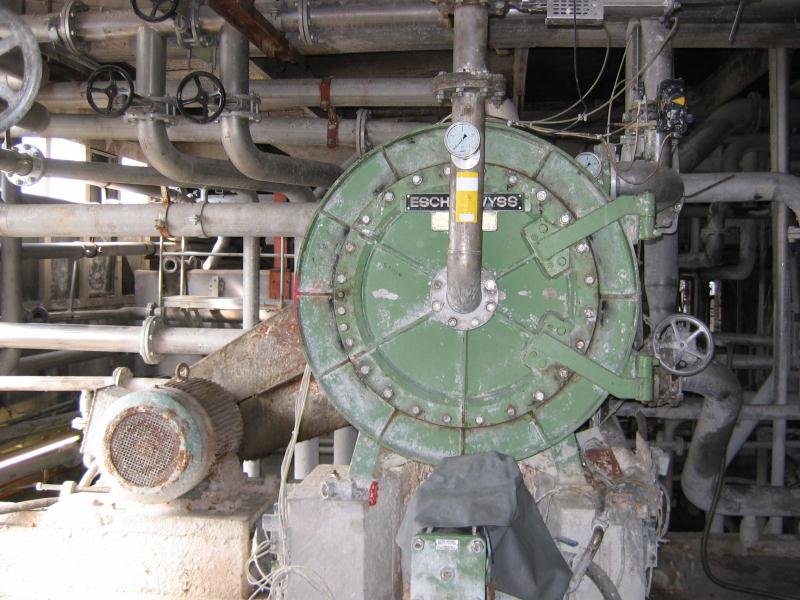

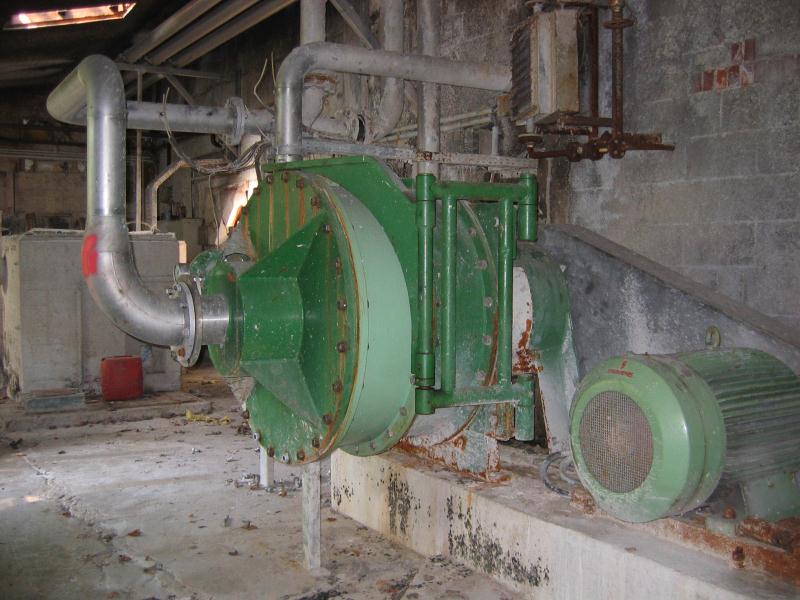

Bottom Wire with - Step-Diffusor Headbox, make

ESCHER WYSS, with tapered manifold and manually adjustable adjustment spindles |

|||

|

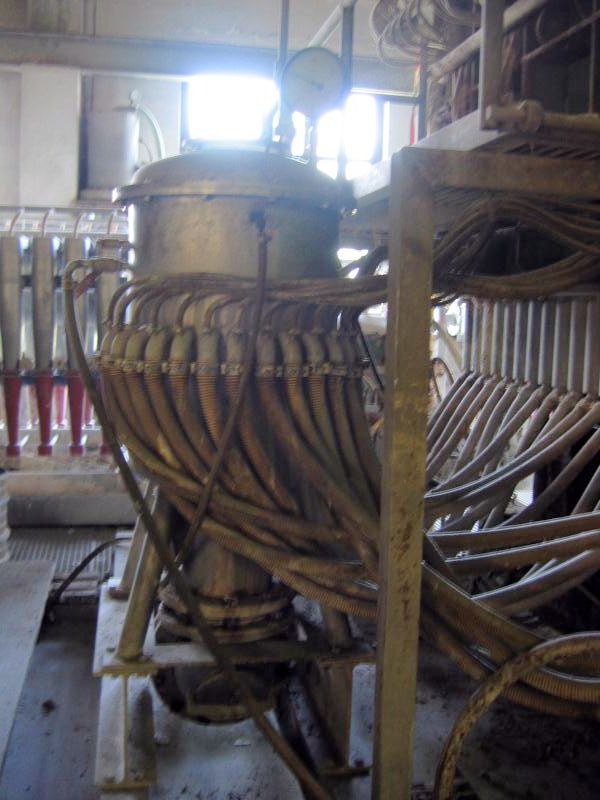

Top wire with - Pressurized Headbox with round

distributor and dilution water cross profile control, manually adjustable. |

|||

|

Press Part with - 3 straight-thru presses, all with own bottom

felt run and all felt conditioning equipment |

|||

|

Dryer Part with - 1st Pre-Dryer group

with 7 drying cylinders, 1 of them app. 700 mm diameter, 6 of them app. 1500 mm

diameter, 3 bars gauge steam pressure, with top and bottom fabric |

|||

|

1 Coating Station with -

1 Cooling Cylinder 1250 mm

diameter |

|||

|

1 Machine Calander, make Küsters, with 4

calander rolls including 1 swimming roll. |

|||

|

1 Quality Control Scanner for measuring of

basis weight and moisture profile, make MAHLO |

|||

|

1 Pope Reel, hydraulic, designed for max.

1800 mm reel diameter |

|||

|

Machine drive by line-shaft with central steam-motor,

make Spilling |

|||

|

1 Slitter Rewinder make JAGENBERG, with 6 slitting knifes, designed for max. 1000 m/min working speed. |

|||

|

1 Reel Wrapper, semi automatic, make LAMB

|

|||

|

Spare Parts :

included as far as available Payment : 100 % payment to be made before

start of dismantling. |

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|

|