| SECOND HAND MACHINE |

| |

| SC-23005 |

2800mm Corrugated Paper Machine |

|

1 second-hand Fourdrinier-Type Paper Machine Make :

Over Meccanica Production Efficiency : 90 % (reffering to time) |

|||

|

Scope of Equipment |

|||

|

Stock and Water System |

|||

|

1 Pulper, make VOITHm, type AP20 including

heavy reject trap and Contaminex pump

|

|||

|

Paper Machine |

|||

|

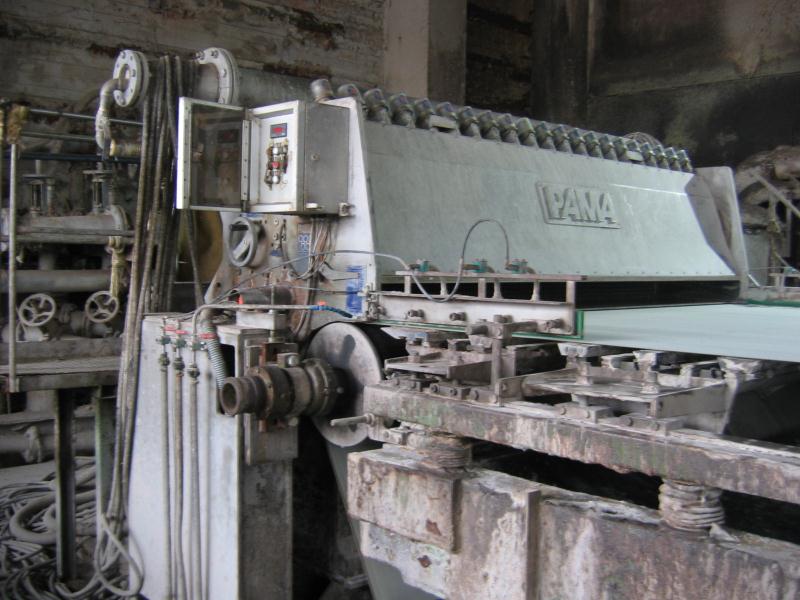

1 Hydraulic high-turbulence headbox with step-diffusor (4-row), make PAMA, with round distributor (Dr. Schultz) and cross profile control by manual dilution water control. |

|||

|

1 Wire part, made of steel and cast iron with multi-layer wet-part painting, electric wire stretchers, pneumatic wire guides, forming board and flat suction boxes with ceramic covers, foils and hydrofoils with plastic covers, suction couch roll 810 mm diameter, forward wire drive roll 550 mm diameter. |

|||

|

1 Couch Broke pulper including agitator and pumps. |

|||

|

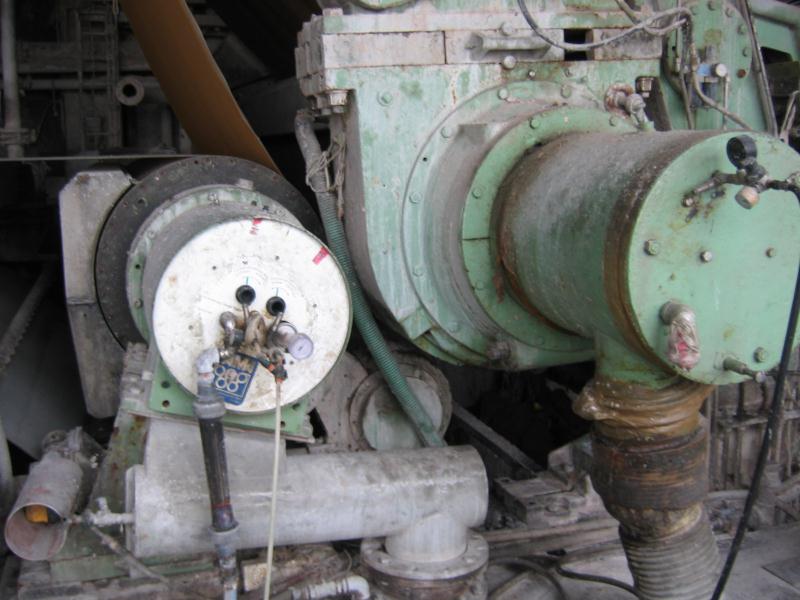

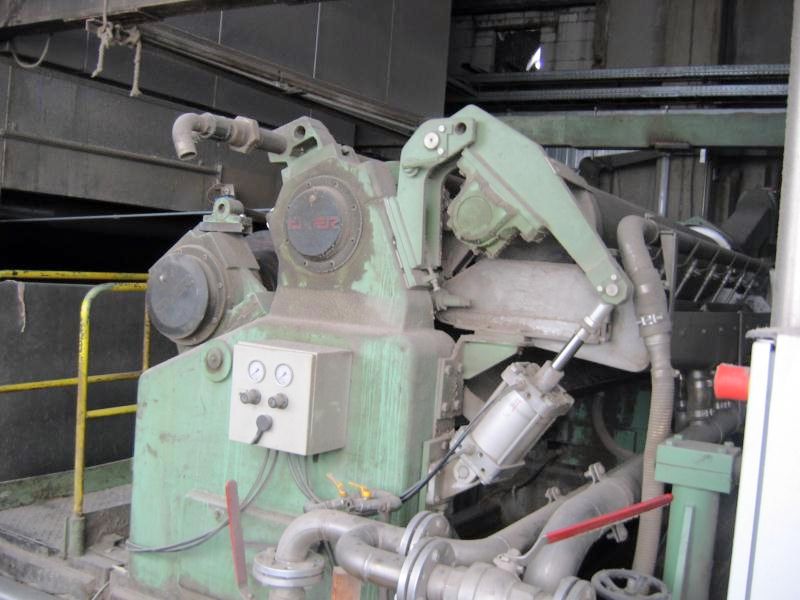

1 Press Part, type DUO-CENTRI, with suction pick-up roll app. 960 mm diameter with drilled and grooved PU-cover, including top felt, 1st nip app. 60 kN/m linear nip pressure against central press roll app. 1000 mm diameter with smooth Green Granite cover, 2nd nip app. 120 kN/m central roll against press roll app. 570 mm diameter with PU-cover, grooved, incl. top felt. Felt runs incl. felt conditioning equipment. |

|||

|

|

|||

|

Dryer Part with following configuration -

Pre-dryer Part with totally 28 drying cylinders 1500 mm diameter, 5 bars |

|||

|

-

After-dryer Part with totally 12 drying cylinders 1500 mm diameter, 5 bars |

|||

|

Dryer fabric run with electric stretchers and pneumatic guides. |

|||

|

Doctors oscillating |

|||

|

Hood and ventilation system with hood, make LANGBEIN & ENGELBRACHT, closed design with forced air flow and heat recovery system, pocket ventilation, dew point control, electric operated lifting doors, web-break detectors. |

|||

|

1 Size Press, inclined design, with starch application system (Film-press type), make WOLFF, including starch preparation system, make CELLIER |

|||

|

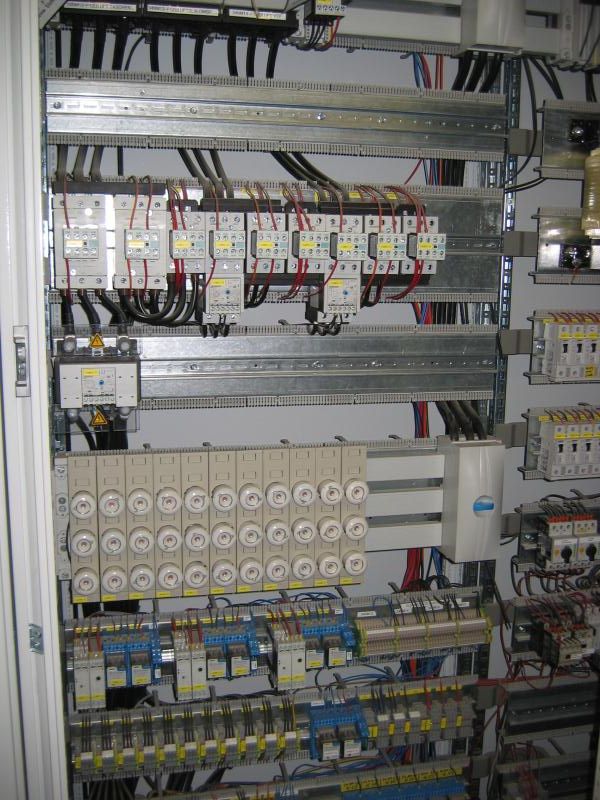

1 Quality-Control Scanner, make PROTAGON (MEASUREX), for measuring of basis weight and moisture CD and MD profile. |

|||

|

1 pneumatic Pope Reel, with turn-up system, make IBS, type RC2300 |

|||

|

|

|||

|

Finishing House Equipment |

|||

|

1 Slitter Rewinder, make APROCART, 2800 mm working width, 3 installed slitters (+ 10 spare slitters), max. speed 2000 m/min. |

|||

|

1 Core Cutter, make HANSSEN |

|||

|

|

|||

|

Supply Systems |

|||

|

1 Steam Boiler |

|||

|

1 Steam Boiler |

|||

|

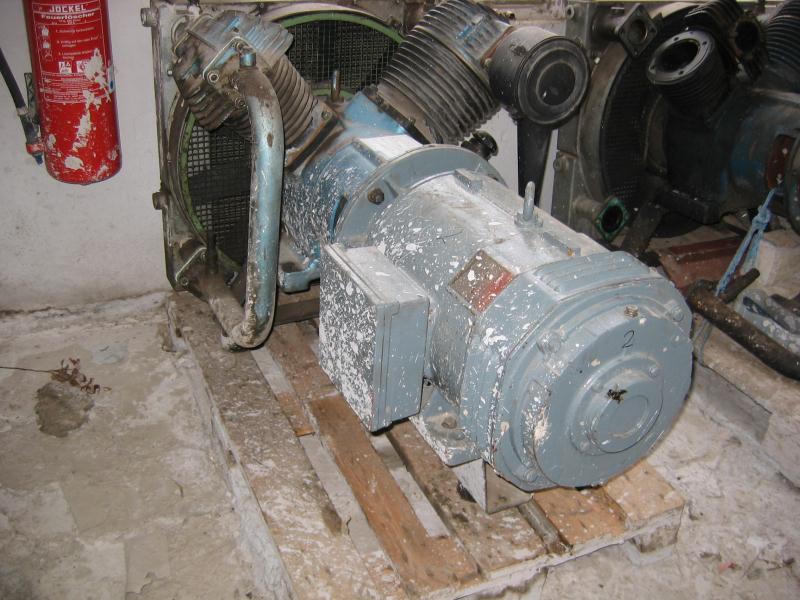

4 air compressors |

|||

|

1 Air Compressor

|

|||

|

Spare Parts : included as far as available Technical Documentation : included as far as available Location : Germany Condition :

Shut down in Sept. 2008. Still installed. |

|||

|

Payment Conditions : Full price must be paid prior to start of dismantling. Payment details to be discussed. |

|||

|

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|

|