1.

Introduction of Heat Roll

|

Although

anybody did not take much interest in the roll heat generated by former calender,

it was known well enough that the roll heat produces an effect on paper'ssmoothness

and luster.

The

reason why the heat of roll was not a matter of one's concern is that roll temperature

changed up to 10¡£C or more luster of paper became unstable and heat

roll was applied habitually only for forming up by calender because steam was

need

as a heat source for heat roll.

Recently

hot roll became the object of one's attention to get paper smooth and luster with

less nip pressure.

Heat

roll was developed as a roll which is available to make flesh of roll cell thin

as far

as possible and equally temperature of roll face with using warm as heat water as

a

heat source.

In

the past, the rotary joint which can stand rotation at high speed was not developed.

However,

T company in U. S. A. have developed the joint which can fully bear high speed

rotation

up to 4 inch caliber and vibration of machine calender roll. It was applied to paper

mill

and proved it excellency. Heat

roll was adopted at first as an middle roll for super calender and met with good

results.

And

then it was adopted to newsprint making machine in order to cope with the tendency

of

light weight newsprint and it is apt to be adopted to high and middle grade printing

paper owing

to the unexpected good results.

|

|

2.

Structure and feature of Heat roll

|

|

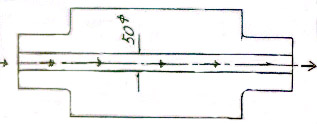

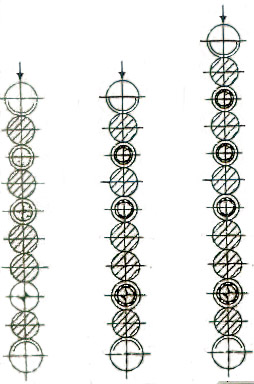

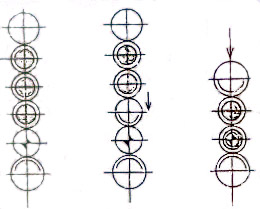

D.

Small Center Hole Type

|

|

|

This

roll was used in the past. It price is cheap.

But it is used usually in case of forming-up

because it makes big difference between

a fluid steamily inside of the roll and

temperature of roll face and has some faults

such as increasing in temperature change

toward the shaft.

|

|

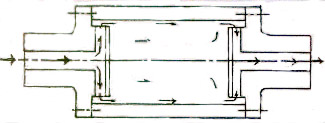

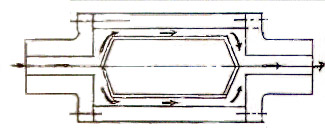

A.

Hollow Assembling Type

|

|

|

This

roll is simple in structure and is used frequently

for machine calender.

The

temperature difference between inside and

outside of roll is limited, temperature change

toward shaft is within 1¡£C and volume

of warm water become in ceasing with

capacious inside measurement of the roll.

And also it is equivalent for the first grade

pressure tool in case of using more than

100¡£C warm water as heat source.

|

|

B.

Diskplacer Type

|

|

|

This

roll is used mainly for super calender of which

face needs 100¡£C temperature and more.

Its

fluid in volume becomes decreasing because the

temperature change toward shaft becomes below

0.5¡£C despite small difference of external temperature

of roll.

It

is not used for machine calender due to complicated

structure, expensive price, unbalanced inside

disk placer and maintenance problems.

It

is not equivalent for the first grade pressure tool

because of pressing inside measurement.

|

|

|

|

3.

Examples of actual use of Heat Calender roll

|

|

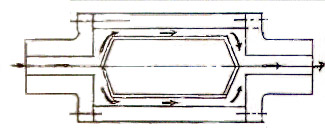

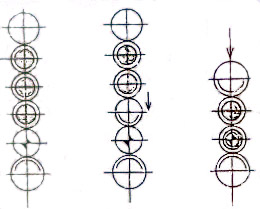

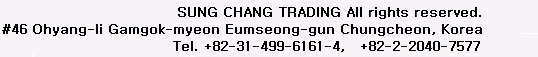

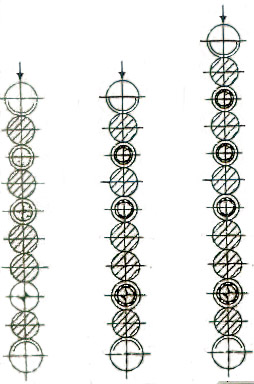

1)

Machine Calender

|

|

|

|

|

|

There

are many cases that two or three units of

heat roll are used for machine calender. In

case that two units of roll are used, some of

paper mills produce paper with less pressure

by 20-30% than former NIP pressure when

they are operated under equal smoothness and

luster.

|

|

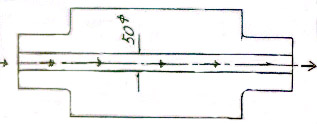

2)

Super Calender

|

|

|

Two

to four units of Heat Roll are usually used for

super calender. In this case, it is possible to

reduce NIP pressure by 15 percent when they

are operated under equal smoothness and luster.

The

quantity of pack elastic roll is reducing very much

to control temperature of middle roll.

|

4.

Effectiveness of Heat Roll

|

Smoothness

Such

smoothness as is obtainable from normal calendering with high NIP pressure can

be derived from low NIP pressure by using heat roll.

Luster

As

for luster, it is as same as smoothness.

Bulkiness

For

bulkiness the influence of temperature is more powerful than that of NIP pressure.

Brightness

Brightness

is affected more by influence of NIP pressure than that of temperature.

Paper

brightness is not changed in accordance with temperature change but NIP pressure

change affects paper brightness.

Opacity

Opacity

becomes decreasing to some extent as calendering temperature is rising.

However,

opacity is affected more qreatly by NIP pressure than temperature.

Suitableness

of printing

Paper

calendered with less NIP pressure under high temperature makes its face rough

and

brings good results from printing test.

Suitableness

of printing becomes better than smoothness and gross by adopting heat roll.

Improvement

of difference between inside and outside

It

is possible to improve the difference between two sides of smoothness, gross etc

in

accordance with quantity of heat roll and selection of place.

|

|

5. Merit

in using heat roll

|

a)

The time for forming-up by calender can be reduced.

b)

If the smoothness is equal, stable operation can be done with less NIP pressure

and

equal luster.

c)

In case of B.C Type ( Hollow assembling roll ) temperature difference between fluid in

skidding and roll face becomes 3-5¡£C and it is easy to control the surface temperature.

In

case of D type ( Center Hole Type ), temperature difference between inside and outside of roll becomes 30¡£C - 40¡£C, and temperature change towered shaft becomes

over 5¡£C.

d)

Since temperature difference becomes within 1¡£C the roll operates under same precision

as grinding.

e)

Due to large quantity of flowing oil stuff within roll temperature of roll changes

slightly when paper is passing through roll even though temperature of paper is not equal.

f)

If temperature of roll face changes slightly cold wind can be less used. Roll can

be rarely changed by using cold wind and grinding cycle can be extended owing to equal abrasion

of roll.

g)

Roll temperature other than heat roll difference slightly.

h)

It is possible to cope with external factors so that temperature of roll face changes without restraint. It is able to improve the equality ratio of products.

I)

The quantity of pack in elastic roll can be reduced very much in case of adopting

two to

three units of heat roll for super calender.

|

|

6. Comparative

table of Heat Roll

|

Heat

roll has been using in large quantities in the field of paper rubber and vinyl industries.

Hollow

roll for paper mill and roll for rubber and vinyl industries are excellent in precision.

There

are two kinds of roll ; hollow assembling roll and roll with good thermal efficiency.

They

are subject to variation according to method of manufacturing, precision of roll

and price.

Please

refer to following items to adopt what kind of roll for your purpose.

|

|

ITEMS

|

Bored

Roll

|

Hollow

Roll

|

Hollow

Assembling roll

|

Drilled

Roll

|

|

Method

of manufacture

|

Conventional

Type

|

Conventional

Type

|

Contrifugal

Casting

|

Contrifugal

Casting

|

|

Material

|

Cast

Iron

|

Cast

Iron

|

Cast

Iron,

Forged

Steel

|

Cast

Iron,

Forged

Steel

|

|

Structure

|

Monolithic

|

Monolithic

|

Assembling

|

Monolithic,

Assembling

|

|

Blowhole

|

Existence

|

Existence

|

Petty

|

Petty

|

|

Processing

|

Inside

casting shot

|

Whole

surface

processing

|

Whole

surface

processing

|

Whole

surface

processing

|

|

Out-diameter

of Roll

|

810mm

|

810mm

|

1,200mm

|

1,350mm

|

|

Length

of Roll

|

3,000mm

|

5,500mm

|

7,200mm

|

8,800mm

|

|

Chilled

depth

|

10mm

|

10mm

|

7-35mm

|

7-35mm

|

|

Surface

Hardness

|

HS72°±2

|

HS74°±2

|

HS76°-

85°

|

HS72°-

85°

|

|

Accuracy

|

Bad

|

Moderate

|

Good

|

Good

|

|

Price

|

Low

|

Low

|

Moderate

|

High

|

|

Balance

|

Bad

|

Moderate

|

Good

|

Moderate

|

|

Temperature difference

|

More

than 10°C

|

More

than 10°C

|

2°C

- 4°C

|

±1°C

|

|